Your Journey with Bleu Lab

New Product Development

From inception to completion

Product excellence

Our design team

Packaging and branding

Product excellence

Our design team

Packaging and branding

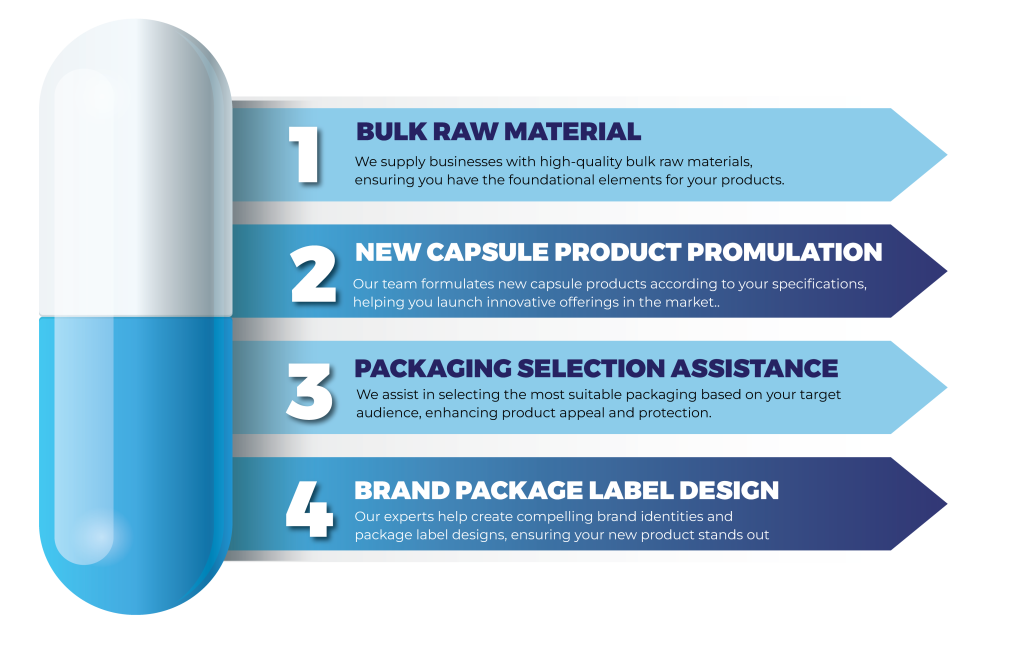

What We Offer

At Bleu Lab, we specialise in providing comprehensive support throughout the product development process, from initial research to final production. Our team works closely with clients to ensure each step is handled with precision and care, whether you’re developing a new formula or scaling up an existing one. Below is an overview of our process, designed to ensure your product meets the highest standards while delivering exceptional quality and efficiency.

Gather all relevant client details and finalise the Non-Disclosure Agreement. This step includes researching and sourcing raw materials to conduct an initial cost assessment and discuss project feasibility.

Confirm and approve the initial cost estimates.

Unique market position

We provide two flexible pathways for our clients

Ready-made formulas

Present us with your existing formula, and we will expertly manufacture it into high-quality batches.

Concept development

Share your idea with us, and we will guide you through the formulation process.